Biotin, also known as vitamin B7 or vitamin H, has become one of the most popular dietary supplements worldwide, primarily marketed for supporting hair, skin, and nail health. If you’ve ever wondered exactly how these small but powerful supplements make their way from raw ingredients to the bottles sitting on pharmacy shelves, you’re not alone. The manufacturing process behind biotin supplements involves several precise stages, each designed to ensure potency, purity, and safety for consumers. Understanding this process can help you make more informed choices about the supplements you purchase and use.

The production of biotin supplements combines pharmaceutical-grade manufacturing standards with quality control protocols that satisfy regulatory requirements across multiple countries. Whether the biotin in your supplement comes from natural extraction sources or is synthesized through chemical processes, the end goal remains the same: delivering a consistent, effective dose of this essential B vitamin in every capsule or tablet. This article walks you through the complete journey of biotin supplement manufacturing, from raw material sourcing through final packaging and testing.

Raw Material Sourcing and Selection

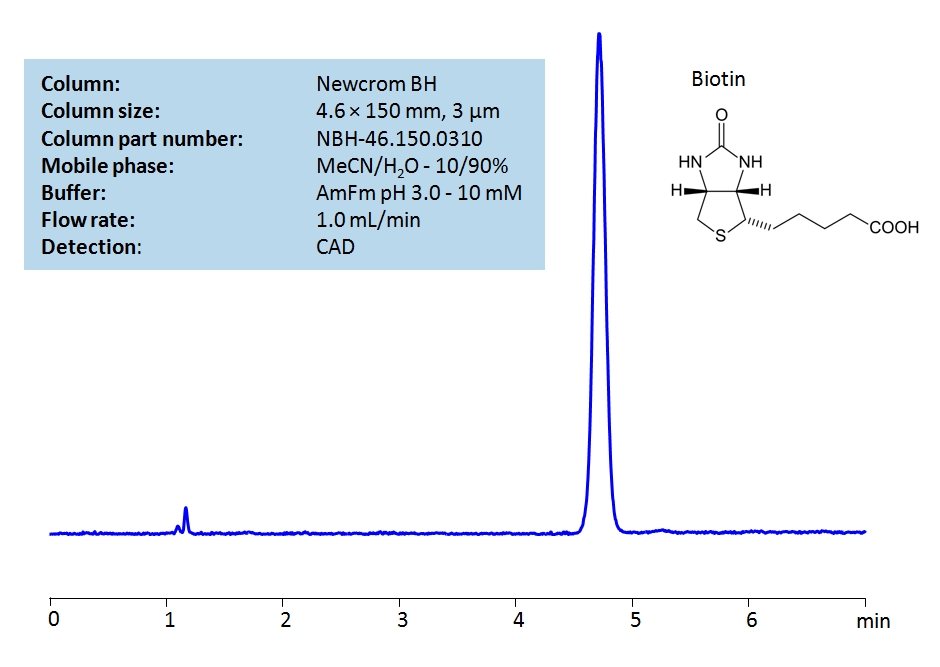

The foundation of any high-quality biotin supplement begins with sourcing pure biotin raw material. Manufacturers typically source biotin in one of two forms: D-biotin (the naturally occurring, biologically active form) or DL-biotin (a synthetic mixture). D-biotin is generally preferred for supplements because it matches the form found in food sources and utilized by the human body.

Suppliers of biotin raw material must provide certificates of analysis documenting purity levels, typically exceeding 98% for pharmaceutical-grade biotin. Manufacturers verify these certificates through their own testing before accepting shipments. The raw biotin appears as a white crystalline powder that is highly sensitive to moisture and light, requiring careful handling and storage upon arrival at manufacturing facilities.

Beyond the biotin itself, manufacturers source additional excipients—substances that help form the final dosage form. These may include microcrystalline cellulose (a filler), magnesium stearate (a lubricant to prevent sticking during manufacturing), silicon dioxide (a flow agent), and various binding agents that hold the tablet together. Each supplier of these excipients undergoes qualification processes to ensure consistency and purity.

Extraction and Synthesis Methods

Biotin supplements on the market today originate through either natural extraction or chemical synthesis, and understanding these methods helps explain cost differences between products.

Natural biotin extraction involves isolating the vitamin from biological sources such as egg yolks, liver, yeast, or certain bacteria. The extraction process begins with hydrolyzing the source material under controlled conditions, then using various separation techniques like chromatography to isolate and purify the biotin. This method tends to be more expensive due to the complexity of extraction and lower yields, but it produces what some consumers perceive as a more “natural” product.

Chemical synthesis represents the most common manufacturing approach for biotin supplements. The synthetic process typically starts from pimelic acid or similar precursor compounds and involves multiple reaction steps to build the biotin molecule. Industrial synthesis achieves high purity at scale, making biotin supplements affordable for mainstream consumers. The resulting synthetic biotin is chemically identical to the natural form—molecular structure and biological activity are indistinguishable.

Some manufacturers produce biotin through fermentation processes using genetically engineered microorganisms. These microbes are cultured in bioreactors where they synthesize biotin as a metabolic product. After fermentation completes, the biotin is extracted and purified from the culture medium. This approach bridges the gap between full natural extraction and pure chemical synthesis.

Why Synthetic Biotin Dominates the Market

The vast majority of biotin supplements use synthetically produced biotin due to cost efficiency and scalability. Synthetic production allows manufacturers to produce consistent, high-purity biotin at industrial scales that natural extraction simply cannot match. The chemical structure of synthetic biotin is identical to that found in nature, meaning your body processes it in exactly the same way.

Formulation Development and Design

Before production begins, formulators design the supplement’s final composition. This involves determining the appropriate dosage strength (common formulations include 5,000 mcg, 10,000 mcg, or higher doses), selecting the dosage form (capsules, tablets, softgels, or liquid), and choosing any complementary ingredients.

For capsule formulations, manufacturers typically use vegetarian cellulose capsules or traditional gelatin capsules. The biotin powder is combined with excipients in specific ratios to create a fill material that flows consistently during encapsulation. Tablet formulations require additional steps, including compression forces that shape the mixture into solid tablets.

Many biotin supplements include additional ingredients intended to enhance effectiveness or address specific health goals. Common additions include zinc (which works synergistically with biotin for hair and nail health), keratin (a structural protein), or various botanical extracts. The formulation team must ensure these ingredients are compatible and stable together over the product’s shelf life.

Manufacturing Process: From Powder to Product

The actual production of biotin supplements follows pharmaceutical manufacturing standards, though dietary supplements face less stringent regulations than drugs. The process begins in a controlled manufacturing environment where temperature, humidity, and air quality are carefully monitored to prevent contamination.

For capsule production, the first stage involves blending. The biotin powder and excipients are combined in industrial blenders for predetermined periods—typically 15 to 30 minutes—to achieve uniform distribution. Operators take samples from different points in the blender to verify homogeneity, as inconsistent mixing could result in some capsules containing more or less biotin than intended.

Encapsulation machines then fill the blended powder into empty capsules. These machines operate at high speeds, capable of producing thousands of capsules per hour. Modern equipment monitors fill weight continuously and rejects capsules that fall outside acceptable ranges. The filled capsules then pass through polishing machines that remove any powder residue from their exterior.

Tablet production follows a similar initial blending process but adds several unique steps. After blending, the mixture undergoes granulation—either wet granulation (using a liquid binder) or dry granulation (using compaction forces)—to create particles with optimal flow and compressibility characteristics. The granulated material is compressed into tablets using high-pressure equipment, then may be coated for appearance, taste masking, or modified release properties.

Quality Control and Testing Standards

Rigorous quality testing distinguishes reputable supplement manufacturers from those cutting corners. Every batch of biotin supplements undergoes multiple analytical procedures before release.

Assay testing determines the actual biotin content in finished products, verifying it matches label claims within acceptable variance limits (typically ±10% in the supplement industry). High-performance liquid chromatography (HPLC) is the standard method for this analysis, providing precise quantification of the active ingredient.

Microbiological testing ensures the product is free from harmful bacteria, yeasts, and molds. Products are tested for total aerobic count, as well as specific pathogens like Salmonella, Staphylococcus aureus, and E. coli. Products failing these tests are rejected and destroyed rather than sold.

Heavy metal testing has become increasingly important as consumers and regulators focus on product safety. Inductively coupled plasma mass spectrometry (ICP-MS) detects lead, mercury, cadmium, arsenic, and other metals that could contaminate supplements from environmental sources or raw material impurities.

Packaging and Labeling Requirements

The final manufacturing stage prepares biotin supplements for consumer use. Packaging serves multiple functions: protecting the product from environmental factors, providing essential information to consumers, and complying with regulatory requirements.

Bottles used for biotin supplements are typically made from high-density polyethylene (HDPE), which provides good moisture barrier properties and compatibility with the product. Some manufacturers use amber or opaque bottles to protect biotin from light exposure, which can degrade the vitamin over time. Each bottle receives a label displaying supplement facts, ingredients list, manufacturing date, expiration date, and any required warning statements.

Child-resistant packaging has become standard for supplement bottles containing more than a month’s supply. These special caps require specific coordination to open, reducing the risk of accidental ingestion by children. While adding slight inconvenience for adult consumers, this feature addresses a serious public health concern.

Choosing Quality Biotin Supplements

Understanding how biotin supplements are made empowers consumers to make better purchasing decisions. When evaluating products, look for manufacturers that provide clear information about their production practices and quality standards.

Third-party testing certifications offer meaningful quality signals. Products certified by NSF, ConsumerLab, or similar organizations have undergone independent verification of content and purity. While certification adds cost that may be reflected in higher prices, it provides tangible assurance that the product contains what the label claims.

Transparent labeling helps distinguish quality products. Manufacturers willing to disclose testing methods, facility locations, and quality certifications demonstrate confidence in their products. Vague claims or missing information may indicate less rigorous manufacturing practices.

Price provides a useful but imperfect quality indicator. Extremely inexpensive biotin supplements may reflect corner-cutting in raw material quality, testing rigor, or manufacturing controls. However, high prices don’t guarantee quality—some premium-priced products rely on marketing rather than manufacturing excellence.

The Bottom Line

The journey from raw biotin to finished supplement involves careful sourcing, precise manufacturing, rigorous testing, and proper packaging. Each stage presents opportunities for quality to diverge, making manufacturer reputation and third-party verification important considerations for consumers seeking reliable products. While the specific details of biotin supplement manufacturing may seem technical, the underlying principle is straightforward: quality supplements result from quality processes at every step of production. When you understand how these supplements are made, you can make more informed decisions about which products truly deliver on their promises.